Enhancing Tensile Response of Polymeric Elements Using Bioinspired 3D Printing: Studying the Effects of Printing Patterns and Process Parameters

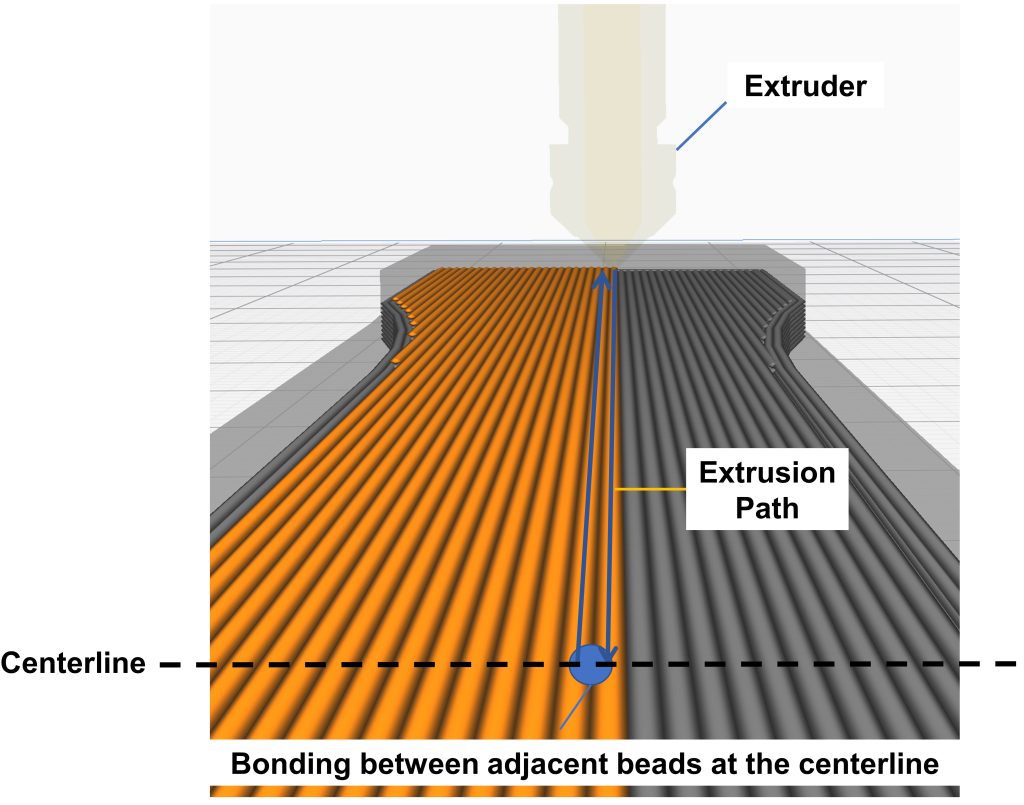

In construction, additive manufacturing (AM) can be used to create structural or non-structural elements such as frameworks, reinforcement, or panels. However, AM technology still requires enhancements in terms of mechanical response of final 3D-printed elements to accommodate the mechanical needs of structural components. This paper evaluates various AM process parameters and bioinspired printing patterns as a means to improve the mechanical performance of 3D-printed polymeric elements. AM processes, including printing speed and nozzle diameter, are studied. Bioinspired patterns, including Bouligand-like, alternating, sinusoidal, grid, triangular, and hexagonal, are investigated and compared to simple parallel pattern. Results of this study suggest that mechanical behavior of 3D printed elements can be significantly enhanced by optimizing the printing speed and nozzle diameter. Incorporating bioinspired architectures in AM such as Bouligand pattern are shown to enhance the mechanical performance. Slower speeds and larger nozzle diameters result in higher tensile strength. Continuous and twisting patterns yield more ductility, while patterns parallel to the direction of the tensile test result in higher strengths. Microscopic images from the fracture surface indicate that larger nozzle diameter enhances intra- and interlayer bonding between consequent printed layers. Additionally, more complex crack propagation is observed in twisting patterns with enhanced elongation before total failure. It is also observed that there is an optimal time of exposure to high temperature for deposited material during AM to improve bonding between adjacent beads. Bioinspired patterns helped maintain higher ductility with similar strength despite encompassing higher porosity than parallel pattern which could be advantageous for material optimization purposes. The bioinspired 3D printed polymeric elements showed tensile properties higher than those of plain polymer filament. Outcome of this study can help optimize both the process and the architecture of 3D-printed elements to enhance their mechanical properties to be used as reinforcing elements for reinforced concrete applications.

View Full Paper