Potential use of lightweight aggregate (LWA) produced from bottom coal ash for internal curing of concrete systems

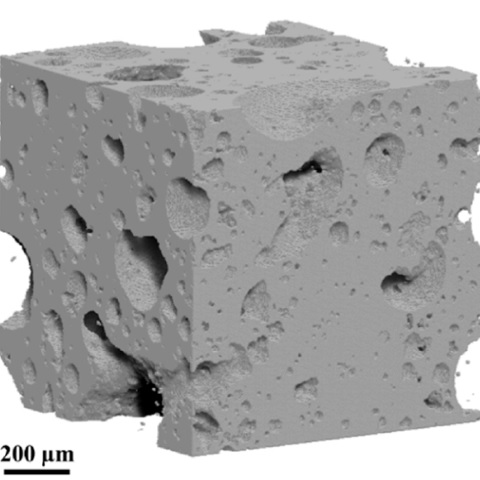

This study evaluates the potential use of a novel lightweight aggregate (LWA), spherical porous reactive aggregate (SPoRA), produced from waste coal bottom ash, for internal curing of concrete. The engineering properties of SPoRA required for concrete internal curing were assessed including specific gravity, porosity, sphericity, water absorption, and water desorption. SPoRA showed a low oven dry specific gravity, ranging from 0.83 to 1.43, accompanied by high porosity which makes it capable of storing the amount of water needed for concrete internal curing. Through X-ray computed tomography (XCT), the high porosity of SPoRA (39.6%– 57.8%, by volume) was measured and confirmed, and its sphericity, which influences the workability of concrete, was evaluated. XCT evaluation also showed that the pore structure of SPoRA is well connected, allowing stored water to move through the pore structure to the outer surface during the self-desiccation of concrete. SPoRA’s 72 h water absorption not only passed the requirements of ASTM C1761 for internal curing (water absorption > 5% and minimum of 85% water desorption at 94% relative humidity, RH), but also showed superior performance in comparison to LWAs available in the market, which were also evaluated in this study. Moreover, the SPoRA desorption isotherms showed its capability for releasing a favorable amount of absorbed water as the internal RH decreases during concrete self-desiccation, thereby providing promising desorption behavior for concrete internal curing and can be a promising LWA for internal curing of concrete.

View Full Paper

Off-spec fly ash-based lightweight aggregate properties and their influence on the fresh, mechanical, and hydration properties of lightweight concrete: A comparative study

An off-spec fly ash-based spherical lightweight aggregate (LWA), designated as Spherical Porous Reactive Aggregate (SPoRA), was manufactured through a lab pilot-scale production and its engineering properties, including specific gravity, dry rodded unit weight, water absorption, mechanical performance, and pore structure, were evaluated. Using SPoRA, lightweight concrete (LWC) samples were made and their fresh, mechanical, and hydration properties were assessed and compared with LWC samples made using two commercial LWA available in the US market. The results indicated that fine and coarse SPoRA had 72 h water absorption capacities of 16.4 % and 20.9 %, respectively, which were higher than that of the two commercial LWAs. Higher saturated surface dry specific gravity of SPoRA compared to commercial LWAs led to a higher fresh density for the corresponding LWC. Using X-ray computed tomography, large spherical type pores were observed in SPoRA similar to those in the commercial slate-based LWA. The pore size distribution of SPoRA, characterized by a dynamic vapor sorption analyzer, indicated that more than 97 % of the pores had diameters greater than 50 nm. SPoRA’s average bulk crushing strength was 6.8 MPa which was smaller than commercial LWA and was potentially attributed to the differences in manufacturing processes. Nonetheless, SPoRA LWC with 28 days compressive strength of 29 MPa passed the ASTM C330 requirement and had a comparable strength with LWC prepared with the commercial LWAs indicating lesser importance for the LWA strength. SPoRA LWC had a flowability of 5 % compared to LWC prepared with commercial LWAs having flowability of ≥ 18 %. This observation was potentially related to the fluxing agent used in the SPoRA production. SPoRA had a 70 % degree of hydration at 12 days which was comparable with that of LWC prepared with commercial LWA.

View Full Paper

A thermodynamics-guided framework to design lightweight aggregate from waste coal combustion fly ash

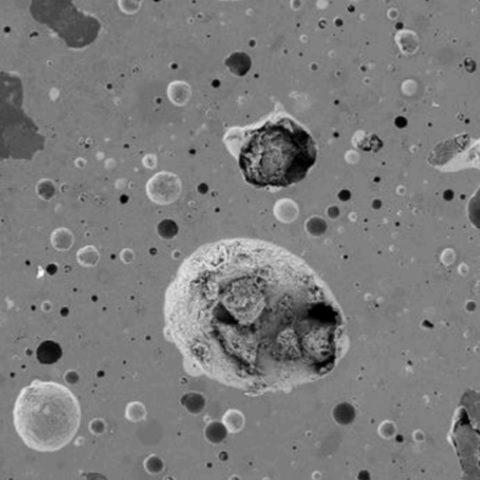

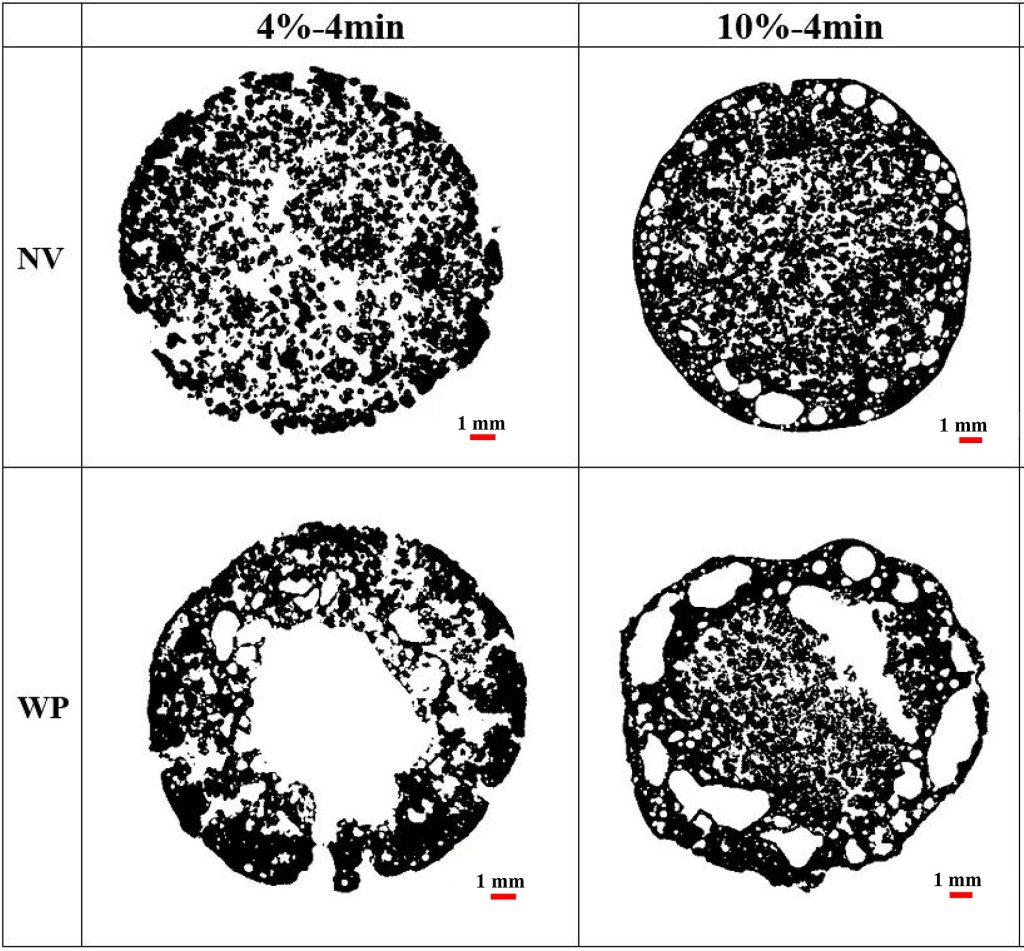

A systematic thermodynamics-based framework was applied to recycle waste low and high-calcium coal combustion Fly Ash (FA) into synthetic lightweight aggregates (LWA) through sintering. The process to successfully manufacture synthetic LWA was investigated, which requires a delicate balance among three phenomena: (i) sufficient liquid phase formation during sintering, (ii) appropriate viscosity for the liquid-solid phase, and (iii) sufficient amount of gas emission to form pores in the LWA. Thermodynamics modeling was used to quantify the formation of the liquid phase during sintering while the fluxing agent and the temperature change. The UrbainKalmanovitch, Browning, and Krieger-Dougherty models were used to quantify the viscosity of the liquid and liquid-solid phase, respectively. A lower bound of 100 Pa•s for the viscosity was found to ensure spherical shape of the LWA. Using thermogravimetric analysis, it was shown that the LWA had a notable gas release potential, owing to the presence of anhydrite and hematite, which could create gas-filled pores in the LWA macromicrostructure. X-ray computed tomography (X-CT) observation revealed the formation of a porous structure for the produced LWA where high calcium FA LWA generally had larger pores compared with low calcium FA LWA. By correlating the X-CT and scanning electron microscopy (SEM) observations and thermodynamic modeling results, it was found that a minimum of 40% liquid phase content (% by mass) is necessary for the formation of gas-filled pores in FA-LWA.

View Full Paper