The term “intelligent manufacturing” describes the process of converting conventional manufacturing processes into more intelligent, flexible, and efficient systems through the use of cutting-edge technologies like artificial intelligence, robotics, the internet of things, big data, and cloud computing. To establish a networked, automated manufacturing environment that can optimize output, boost product quality, and cut costs, it entails the integration of digital and physical systems.

Many different industries, including aerospace, automotive, electronics, healthcare, and many more, can benefit from intelligent manufacturing. It can make industrial processes more efficient, dependable, and predictable. This may result in enhanced customer happiness, improved product quality, and increased productivity. The capacity to gather and examine substantial amounts of data created throughout the production process is one of the main advantages of intelligent manufacturing. This can support waste reduction, production process improvement, and area for improvement. Additionally, real-time monitoring of production processes can be made possible through intelligent manufacturing, which enables producers to spot and fix problems before they become serious.

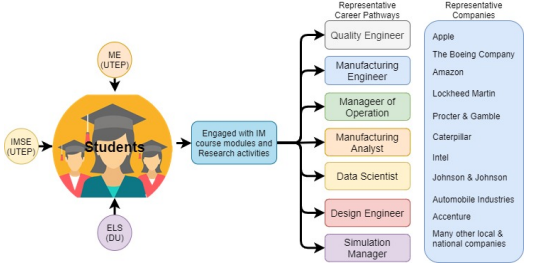

Texas is becoming one of the top locations for American manufacturing companies looking to export their products because to the development of the intelligent manufacturing sector. Due to this, UTEP is in an exceptional position to teach students about intelligent manufacturing techniques. To fulfill the demands of the future workforce, IM development is one of these strategies that must be prioritized. The goal of this collaborative effort between UTEP and Drexel University is to boost students’ career pathways while also improving the curriculum to address these important challenges. Students with subject-matter knowledge and expertise in IM can follow career options based on the current work market.

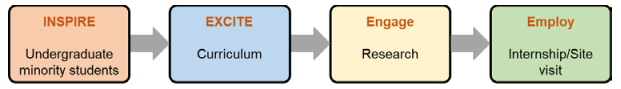

The curriculum will be developed with an emphasis on unique topic courses for undergraduate and graduate students as well as integrated advanced manufacturing courses, with a broad theme of VR robotics, additive manufacturing, production design optimization, and data analytics sector. The initiative for curriculum development will be led by the PD and Co-PDs, who have substantial experience in advanced manufacturing. We designed the pipeline development using the “Inspire – Excite – Engage – Employ” approach.

After completing these workshops and seminars successfully, participants will receive a certificate. The Remote Accelerated Center of Engineering Student Success (Remote-ACCESS) will be in responsible for issuing the certificate.