To improve fuel efficiency and meet carbon-neutral goals, aviation and automotive industries are seeking stronger, more affordable lightweight alloys. Mg and its alloys are promising candidates due to their low density and natural abundance. However, many current Mg alloys suffer from limited strengths that cannot meet industrial needs. Solute clustering at the nanometer scale has been recently recognized to lead to novel and unprecedented strengthening effects in some low-temperature-aged Mg alloys. Although solute clustering is typically regarded as a transitional configuration of solute atoms between random solution and ordered precipitation, its strengthening mechanism is unclear and cannot be explained by simply extrapolating the theories of solid-solution and/or precipitate strengthening.

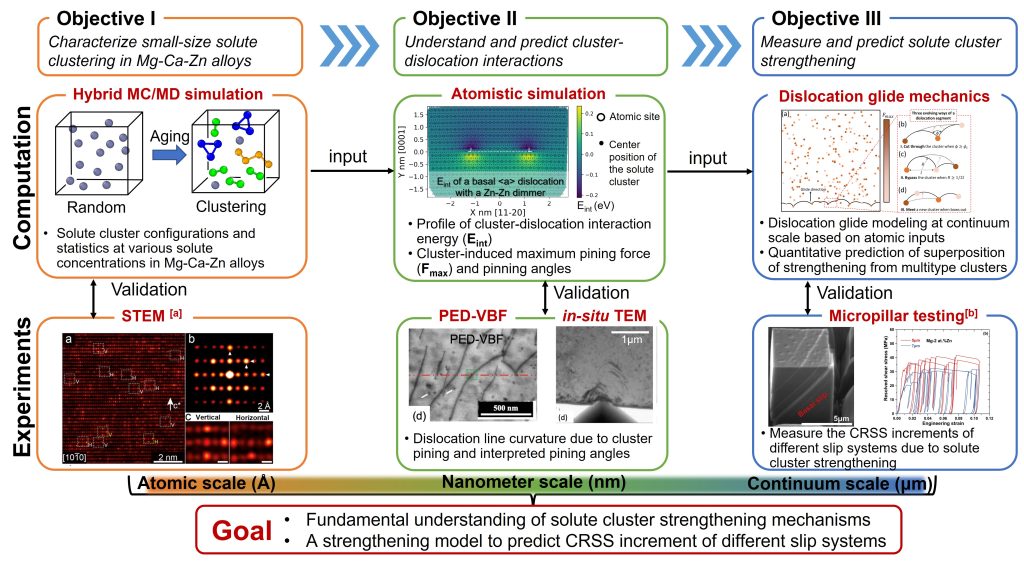

An integrated computational and experimental investigation is performed to elucidate the fundamental mechanisms of solute cluster strengthening across multiple scales using Mg-Ca-Zn as the model system. The hypothesis is that solute clusters of specific chemistry and configuration can offer greater strengthening than that induced by either randomly distributed solute atoms or ordered precipitates with the same number of solute atoms. Testing the hypothesis generates the following new knowledge: 1) chemistry, atomic structure, and number density of solute clusters at the atomic scale; 2) interaction mechanisms between solute clusters and dislocations at the nanometer scale; 3) the effect of solute clusters on dislocation slip behaviors at the continuum scale. The proposed research is developing a transformative multiscale model that integrates the inherent atomic-level information of cluster-dislocation interactions for quantitative modeling of continuum-scale dislocation slip mechanics. This new model could reveal the quantitative connections between the alloy’s yield strength increment and cluster statistics, i.e., the distributions of cluster density, chemistry, and atomic structure. In particular, it aims to explain the circumstances in which cluster strengthening surpasses conventional precipitate strengthening (e.g., Mg-Zn-Ca), as well as the situations where it may not yield the same benefits (e.g., Mg-Zn). This research is a team effort in collaboration with Prof. Kelvin Xie at Taxes A&M University.