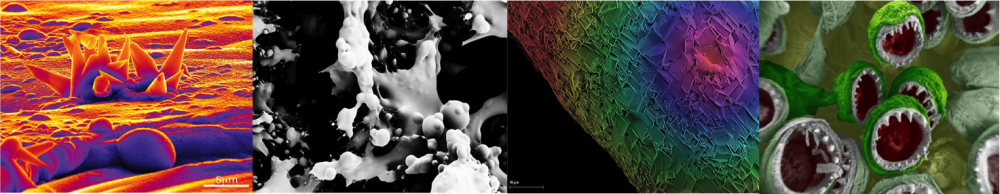

Electrospinning creates non-woven fiber mats with larger specific surface areas and smaller pores than conventional methods of fiber production. Electrospun fibers are expected to have advantages in many applications over fibers produced by traditional methods and in general, the smaller the diameter of a fiber, the better the mechanical properties such as tensile modulus and strength to weight ratios that fiber has. The creation of nano-fibers is desired for the development of filtration membranes and for protective clothing that would restrict airborne chemicals. Additionally, electrospun fibers may offer improved solutions in biomedical applications such as creating improved prosthesis and drug delivery devices.

The process of electrospinning results in the production of continuous fibers deposited as a non-woven fibrous mat by the application of an electric force. When the polymer concentration is high, fibers can form from the utilization of chain entanglement in polymer solutions or melts. More specifically, the polymer solution is advanced through a syringe to form a Taylor Cone, a conically shaped volume of fluid. A voltage drop is created across the jet due to nodes which are created on the pipette and at the collector screen. When the voltage is high enough, the electrostatic force is able to overcome the surface tension force, and a thin jet will form at the bottom of the cone. Due to the induced electric field, the solution in the jet accelerates and thins out over the course of three stages: jet initiation and extension in a straight line, collector (ground) electrode, source electrode, and a solution or melt to be spun. The polymer solution is held in place by a glass syringe with a blunt tip metallic needle of varying size.