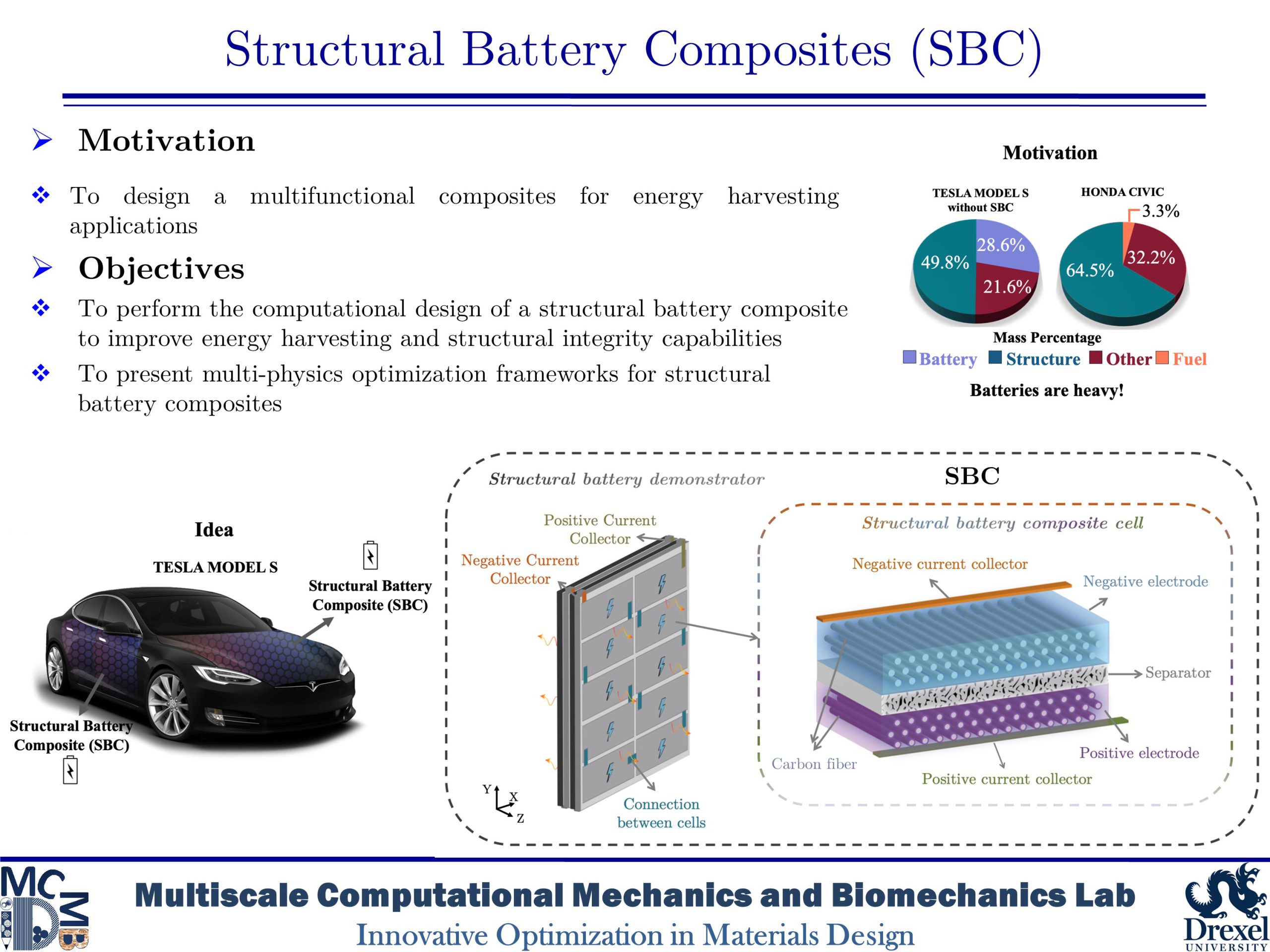

One of the major hindering factors in the development of electric vehicles is that the specific energy of the batteries is low. To put it in illustration, as it is shown in figure (a), the share of battery in the total mass of a typical electric vehicle such as Tesla Model S is about 28.6%, while the share of mass for the source of energy (fuel) in a fairly common gasoline car such as Honda Civic is only about 3.3%. Thus, this is a critical issue for designers that are trying to make electric vehicles as efficient and lightweight as possible. There are two different approaches to tackle this problem. One approach is enhancing the specific energy of batteries as most of the research groups are currently working on. An alternative approach that we are looking into is to take advantage of multifunctional materials enabling us to combine several functions, which can potentially lead to a significant reduction in the mass of electric vehicles.

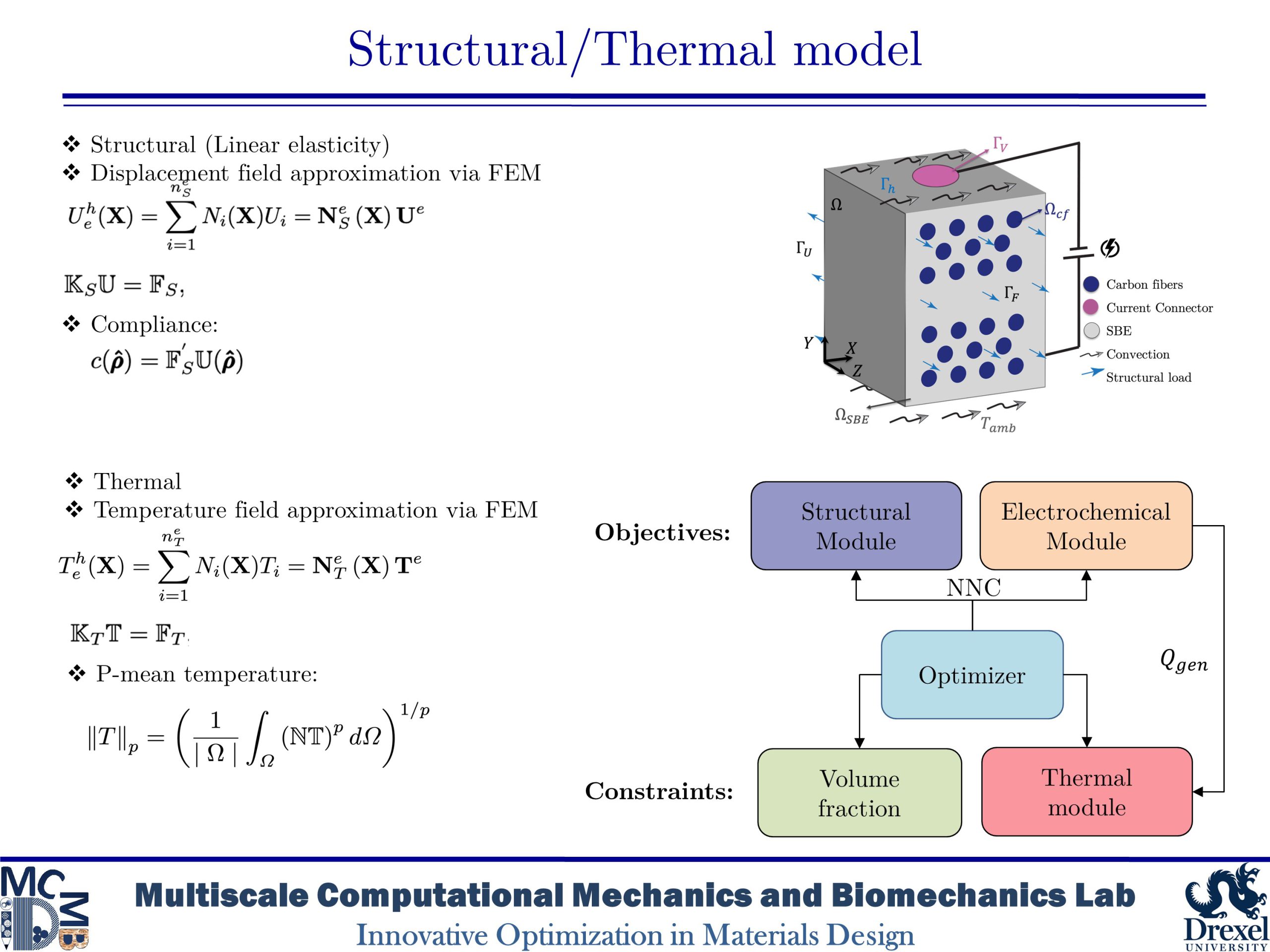

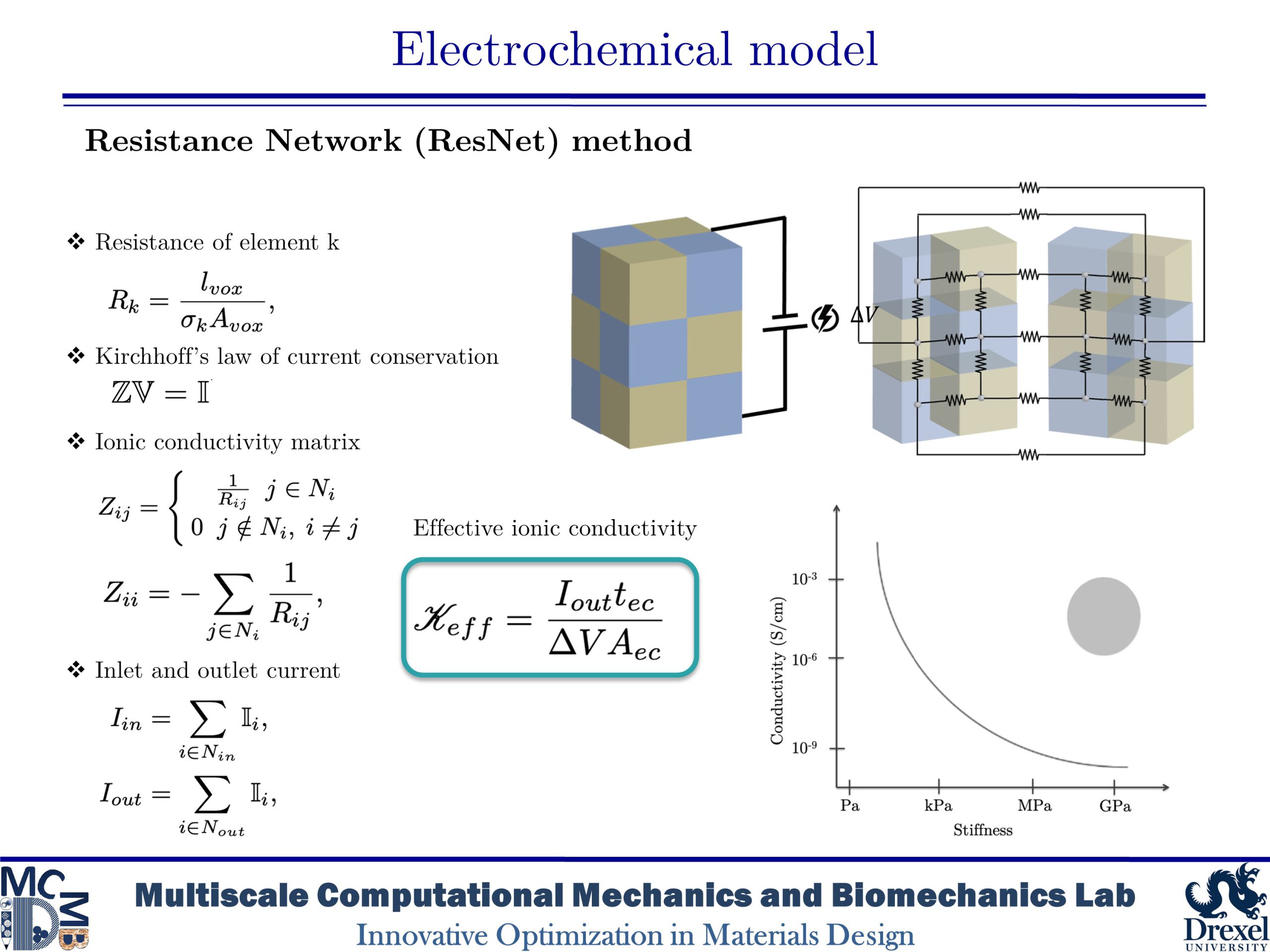

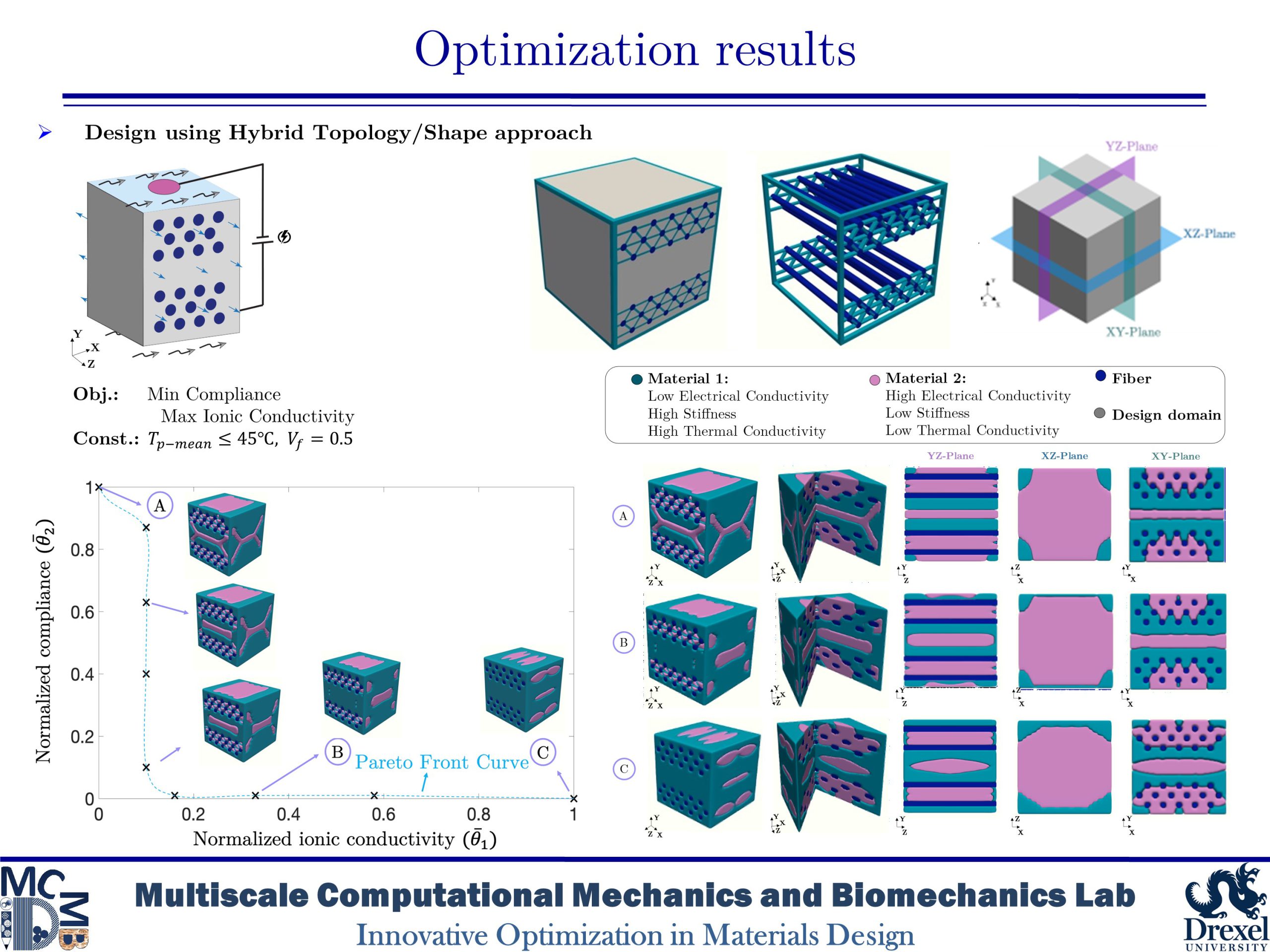

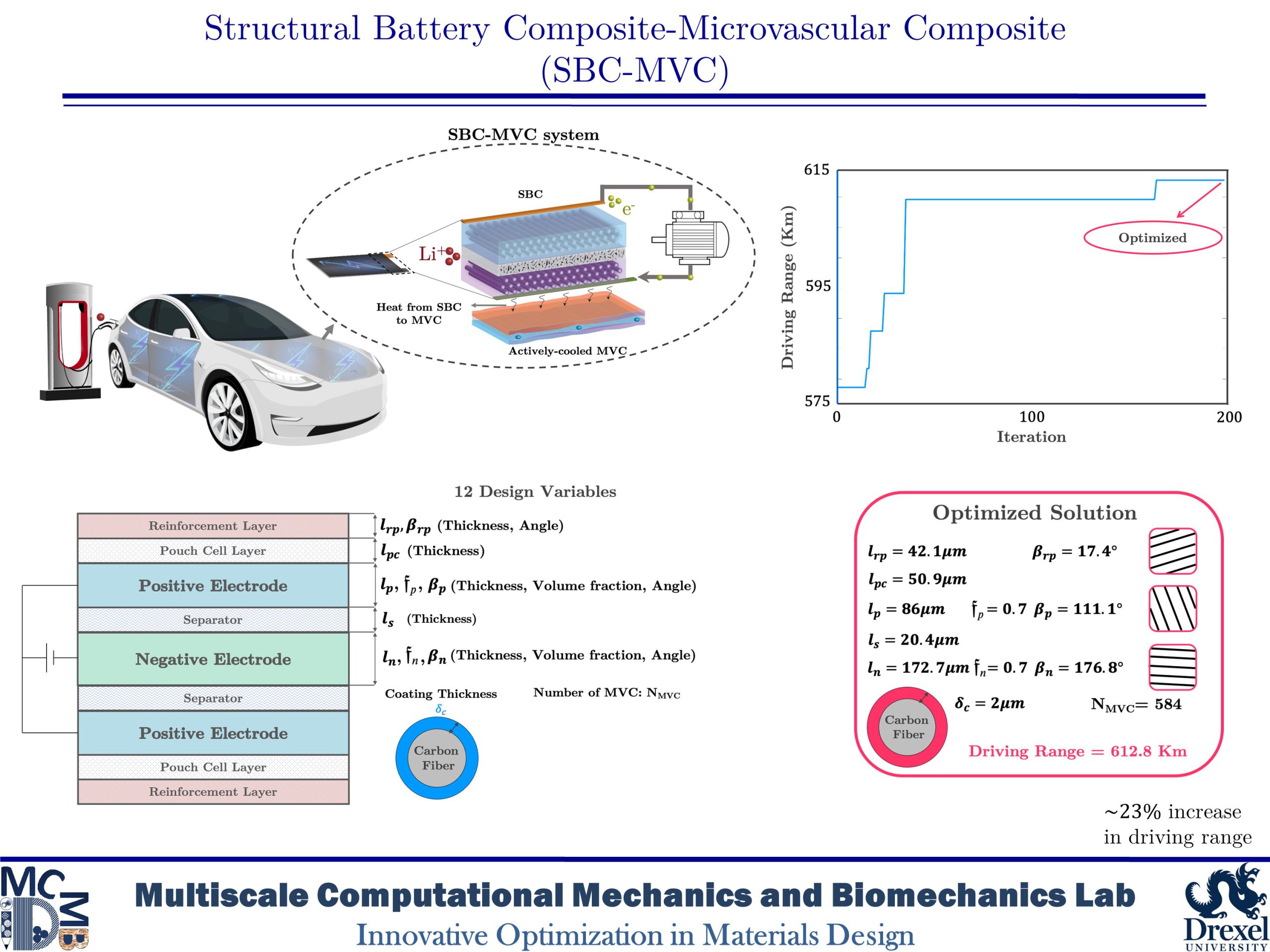

Recently, a class of fiber-reinforced composite (FRC) materials, namely structural battery composites (SBCs) is developed, with the ability to harvest electrical energy in the form of chemical energy while simultaneously provides mechanical integrity in a structural system. For instance, as it is shown in figure (b), SBC can be introduced in different parts of an electric vehicle, e.g. doors, hood, roof, etc. And introducing SBC in electric vehicles has the potential to reduce both the mass of vehicle’s structure and the required amount of battery for that vehicle. These materials are quite promising, but they are still in their early stages of development, and further studies are required for their advancements. The need to fulfill multifunctionality in SBC results in intrinsically conflicting physical property demands. SBC simultaneously requires to provide mechanical integrity and harvest electrical energy, which in general can be conflicting demands. Moreover, electrochemical cyclings generate heat and we need to protect the SBC from overheating. The design of SBC plays a key role in creating a trade-off between these conflicting physical property demands. Thus, one of the most important areas of research on SBC is developing a rigorous multi-physics design optimization approaches.

Related Publications

-

- Pejman, R. and Najafi, A.R., “Multiphysics topology optimization of a multifunctional structural battery composite” Structural and Multidisciplinary Optimization, vol. 66, p 46, 2023.

- Pejman, R., Gorman, J., and Najafi, A.R., “Multi-physics design of a new battery packaging for electric vehicles utilizing multifunctional composites” Composites Part B: Engineering, vol. 237, 109810, 2022.

- Pejman, R., Kumbur, E.C., and Najafi, A.R., “Multi-physics design optimization of structural battery,” Multifunctional Materials, 4 (2), 024001, 2021.