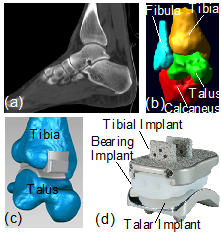

In collaboration with Prof. Siegler (MEM, Drexel University), Prof. Najafi’s Manufacturing PA Innovation Program proposal entitled “Design and Manufacturing Optimization of a Personalized Total Ankle Replacement” has been awarded from the PA Department of Community and Economic Development. Drexel University and Kinos Medical, a young implant design company based in PA, are jointly proposing a design manufacturing approach to conduct an optimization study on the design of a personalized Total Ankle Replacement (TAR) (also called Total Ankle Arthroplasty, TAA). In this study, we combine novel optimization tools, the state of the art in human ankle biomechanics, and cutting-edge manufacturing techniques (e.g., 3D printing in metal and PEEK) for structural shape optimization of the components of TAR implants to create the next generation of TAR designs. Clinically available TARs require the removal of a significant portion of the subchondral bone of the talus. By removing the hard cortical layer of this small and highly porous bone, it loses its strength. To address this crucial issue, our motivation is to design a personalized TAR implant with optimized shape/size/properties by creating patient-specific bone-implant interfaces that match the patient’s underlying bone unique anatomy and therefore, require minimal to no bone resection (Figure 1).