Correlating the particle connectivity of different thickness electrodes on its electrode performance using 1-dimension pair distribution function

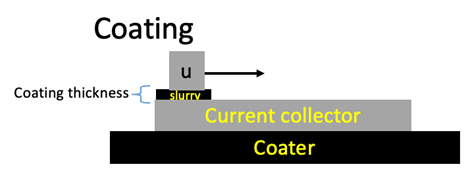

Coating is the core process in the electrode manufacturing of lithium ion batteries (LIBs). Two important coating parameters are coating speed and coating thickness affecting slurry microstructure and final electrode performance. The electrode is composed of active material, binder, and conductive additive. During the processing of the slurry, the coating speed may affect particle connectivity and orders, while controlling coating thickness results in different energy densities of electrodes. This project is to understand how the relationships between processing parameters and electrode microstructure affect electrode performance.

Co-Advisor

Dr. Maureen Tang

Dissertation Title

Correlating the particle connectivity of different thickness electrodes on the electrode performance using 1-dimension pair distribution function

Related Publications

Publications are either being submitted or still in the process of being imported for this topic. Check back later.