Manufacturing

Large sectors of the economy rely on technological advances in materials science to address societal needs. Academic labs more than ever are at the forefront of materials advancement. Yet there is a significant, if not infinite, time lag between material discovery and commercialization. While the reason for this can vary from economic feasibility to raw material shortages, one reason for the discontinuity is the difficulty in manufacturing at scale (which has its roots in economic feasibility). By definition, academics work on scales that are irrelevant to manufacturing production levels, i.e., grams instead of tons, milliliters instead of millions of gallons. Thus, taking a material from an academic lab to full production levels leads to the age-old problem of process scale-up, which means less control and added uncertainty in process control parameters. One typical engineering solution to rein process parameters during scale-up is the Edisonian approach at pilot scale, followed by full-scale operation. While this progression is effective, it is time and resource expensive. Another approach is to try and use existing process instrumentation with new materials, disregarding the fact that the process was designed for a specific material and is ill suited for the new material.

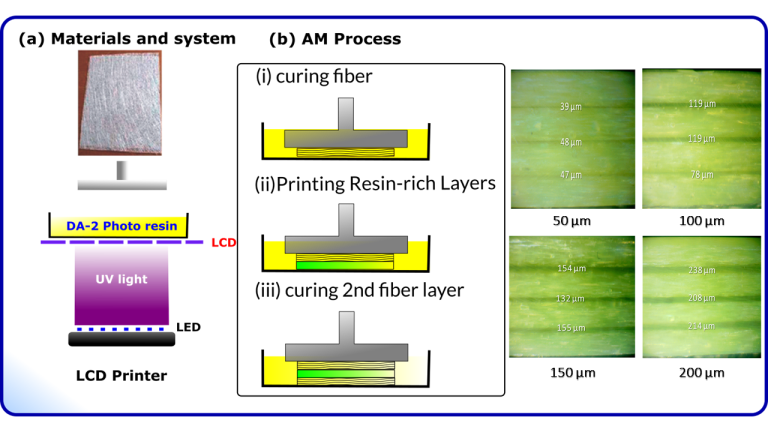

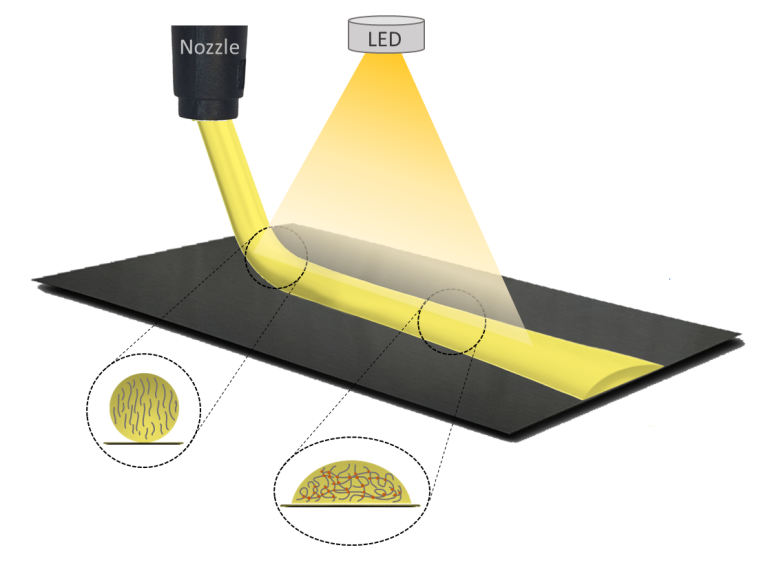

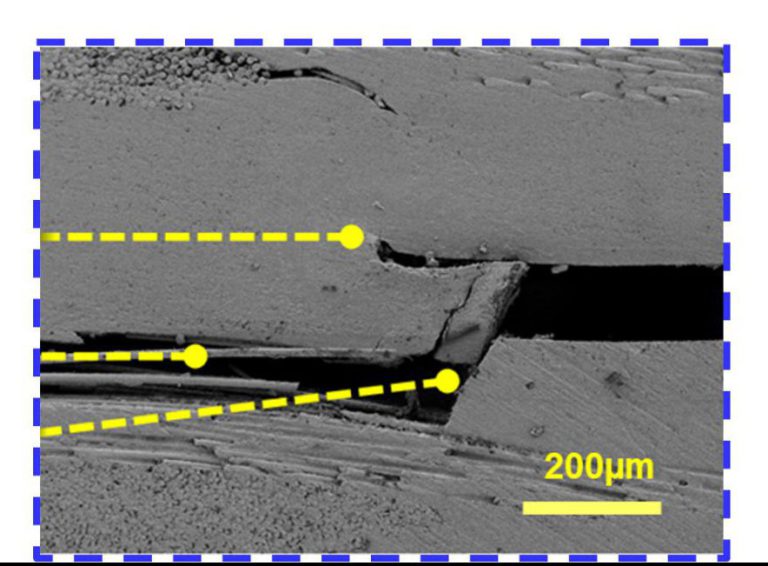

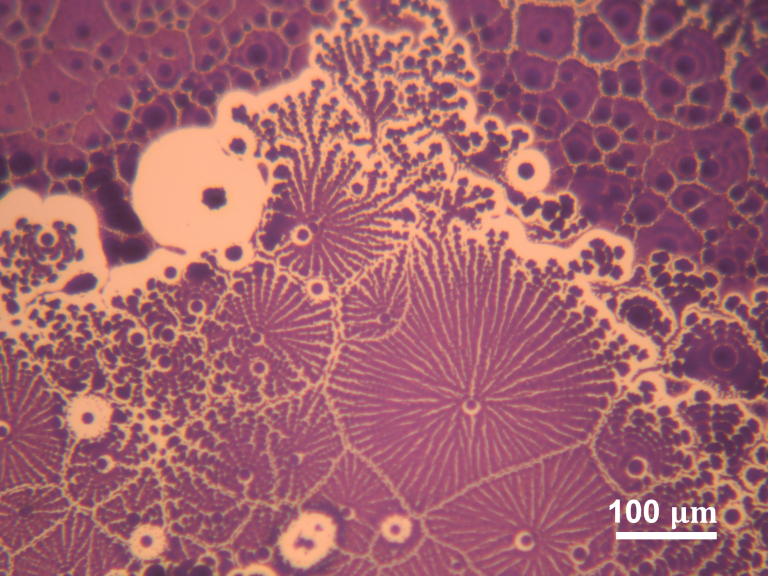

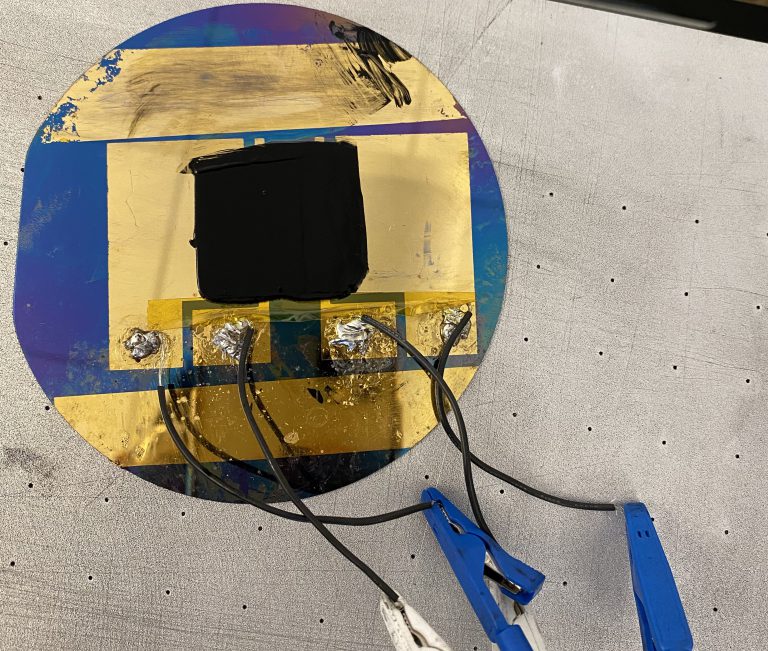

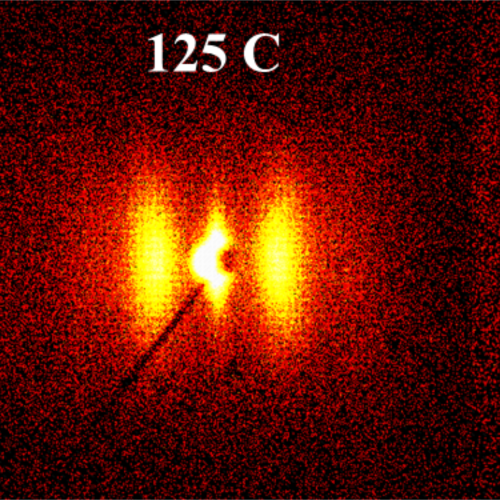

The Alvarez Research Group focuses on curtailing the uncertainty in manufacturing scale-up by developing key chemistry-process-structure-performance relationships to aid in best manufacturing practices to yield targeted end-user part performance. Our approach is rooted in strong fundamentals in colloidal physics, interfacial phenomena (e.g., foams and emulsions), fluid mechanics, rheology, and transport phenomena. These fundamentals are applied to a broad range of problems in the areas of additive manufacturing, thin film manufacturing, fiber spinning, composite manufacturing, spray drying, and more. Materials of current focus are perovskite thin film technology for advanced solar cells, new additive manufacturing processes for composite printing, carbon and polymer fiber spinning, and complex rheological fluid spray drying.

Additive Manufacturing

Research Projects

Publications

Thin Film Manufacturing

Research Projects

Publications

Publications are either being submitted or still in the process of being imported for this topic. Check back later.

Fiber Spinning

Publications

Spray Drying

Publications

Publications are either being submitted or still in the process of being imported for this topic. Check back later.