Determining the Printing Condition by Investigating the Spreading of the filament

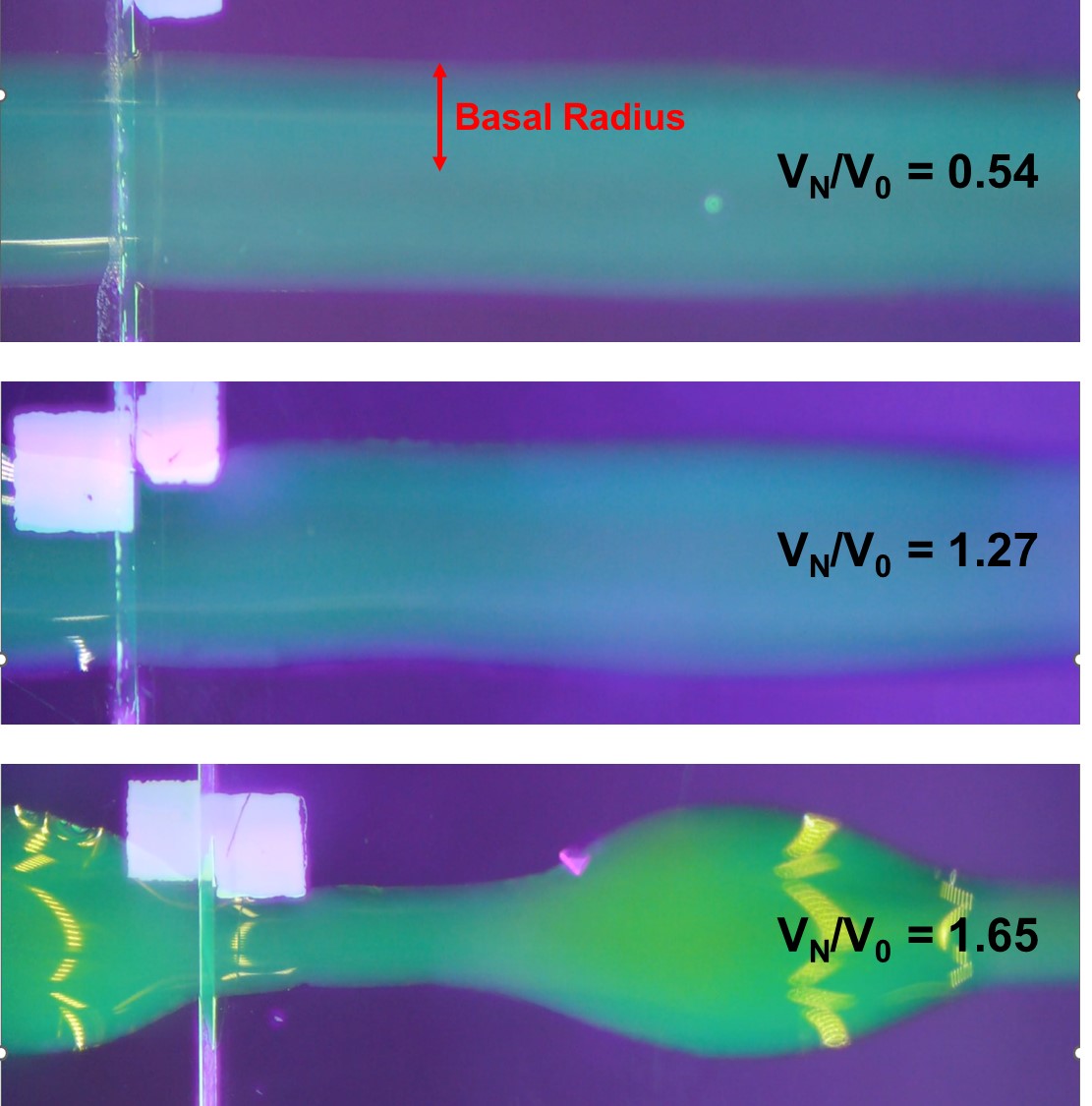

Determining the proper spreading of filament is extremely important for defining the internal structure and mechanical performance of 3D printing products. Prior studies have shown that the spreading of filament is highly affected by the rheological behavior of fluids and printing parameters. For instance, optimum ink viscosity allows maintaining proper filament shape and achieving good interlayer adhesion during the printing process. The printing parameters such as nozzle velocity (VN) and infill rate (V0) have been shown to define the shape of filaments and void formation. In the current work, we use rheology to investigate the spreading behavior for DA2 resin with fumed silica particle mixture to determine the optimum formulation of 3D printing ink and parameters. We found strong shear thinning behavior of DA2 resin with increasing silica particles concentration, and the spreading of the filament was highly dependent on shear thinning behavior. The spreading of filament followed power-law behavior, and it was increased with increasing V0 and VN.