Performance of Additive Manufactured Glass Fiber Laminates

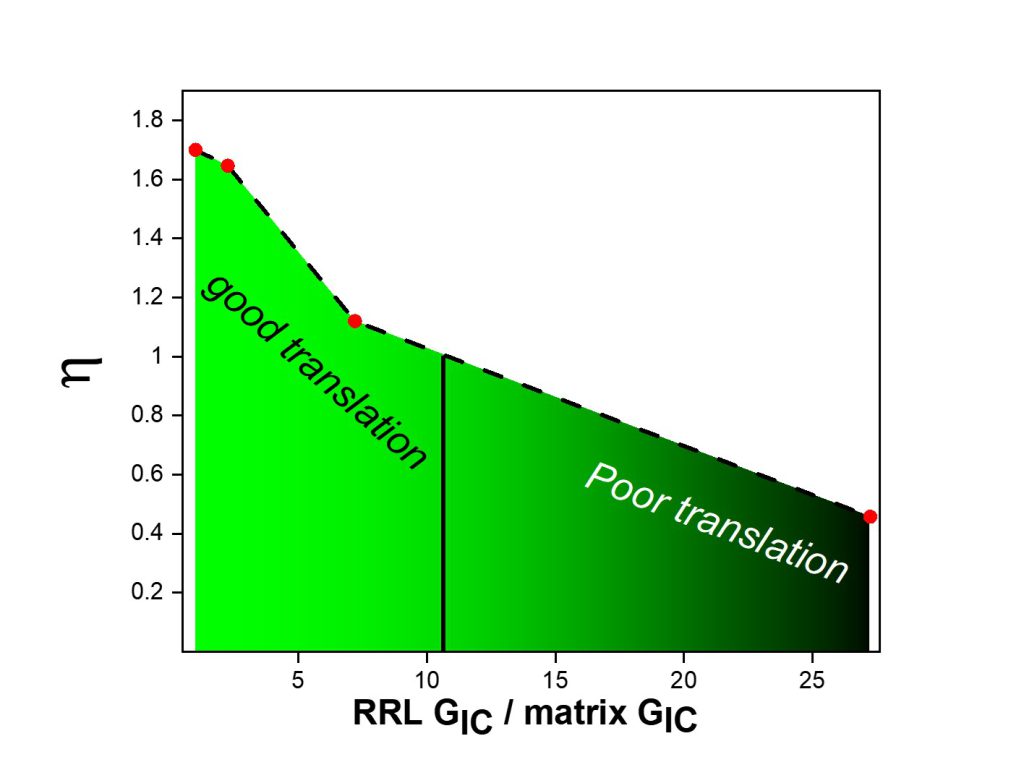

The effect of resins' toughness on composite interlaminar toughness

Additive manufacturing (AM) offers excellent versatility over traditional composite processing techniques. In AM, parts can be designed as a computer-aided model and printed as layers using appropriate slicing.

My research objectives are to develop a process in which laminates can be processed in commercial LCD/DLP printers and the material’s deposition can be controlled by the user at each step. Another objective is the incorporation of resin-rich layers, which are known to affect the laminate’s interlaminar properties. This flexible processing method can then be used to answer fundamental questions about these laminate constituents and to understand how they affect the material’s final performance. Specifically, I looked at the effects of matrix and resin-rich layer properties on interlaminar toughness.